7CF® Second Petroleum Spray Paint is made from thermoplastic acrylic resin and it can be applied by aerosol spray and provide films with excellent performance such as excellent weather resistance, good leveling, strong coverage, fast-drying, high build, and match well with many types of primers.

Low flash point & burning point

Fast drying

Simple construction operation

Good spray atomization

High spray rate

High film fullness

Excellent decorative effect

Superior adhesion and durability

Second petroleum spray paint is widely used for all interior/exterior applications, for surface finishing of iron & steel, plastics, metals, surface-treated wood, glass and other substrates.

Thoroughly remove dirt, grease, oil and water on the surface to be painted.

Fill the recessed part with Poly-Putty Base and smooth it.

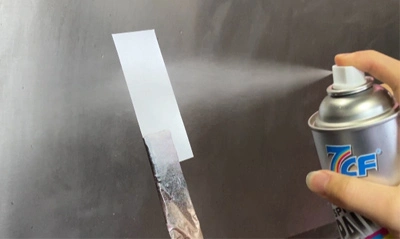

Hold can upright 20-30cm from surface and use your index finger to press down the nozzle to spray in a steady back and forth motion.

Apply in thin multiple layers, thin layers applied every 2 minutes are always better than one thick layer.

Apply in thin multiple layers, thin layers applied every 2 minutes are always better than one thick layer.

If the spray is not finished at one time, turn the bottle upside down and press down the nozzle for 3 seconds to clean out the valve and prevent plugging.

Item | Standard | Remark |

Appearance | Film flat and smooth, no mechanical impurities, accord with the confirmed sample. | Eye test |

Drying condition | Touch dry ≤15 minutes, finger press dry ≤ 1 hours | Under the temperature of 20℃ |

Recommended Thickness | 18-25µ | - |

Volume Solid | 15-25% | - |

Specific Gravity | 0.90-1.15 | - |

Adhesion | ≤2 | Circle Testing |

Hardness | ≥HB | Dry after 48 hours (Room Temperature) |

Gloss | Gloss ≥80; Matt accord with the confirmed sample | 60℃ gloss level, relative moisture ≤ 75 % |

Flexibility | ≤1mm | - |

Spraying rate | ≥98% | - |

Flashpoint | Low | - |

Burning point | Low | - |

Shelf Life | Three Years | - |

ITEM NO. | Container size | Optional sizes |

A-S-002 | 10oz(283g) | 8oz(226g), 9oz(255g) |

GET IN TOUCH WITH 7CF TO LEARN MORE PRODUCT LINES

English

English  Español

Español  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  italiano

italiano  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt