The Chinese government attaches great importance to the protection of the atmospheric ozone layer. In accordance with the United Nations' Vienna Convention for the Protection of the Ozone Layer, the Montreal Protocol on Substances that Deplete the Ozone Layer, and the Kigali Amendment to the Montreal Protocol on Substances that Deplete the Ozone Layer, the Chinese government approved the implementation of the National Program for the Phased Elimination of Ozone-Depleting Substances in January 1993.

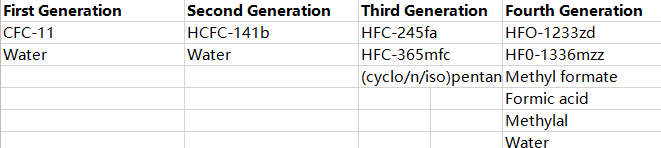

According to the requirements of the National Program, the polyurethane foam industry has formulated a phased replacement plan for blowing agents. The replacement work for blowing agents has been continuously progressing since the early 1990s. The use of the first generation CFC-11 has been prohibited, and the use of the second generation HCFC-141b will also be prohibited in 2026.

Table 1: Classification of Blowing Agents

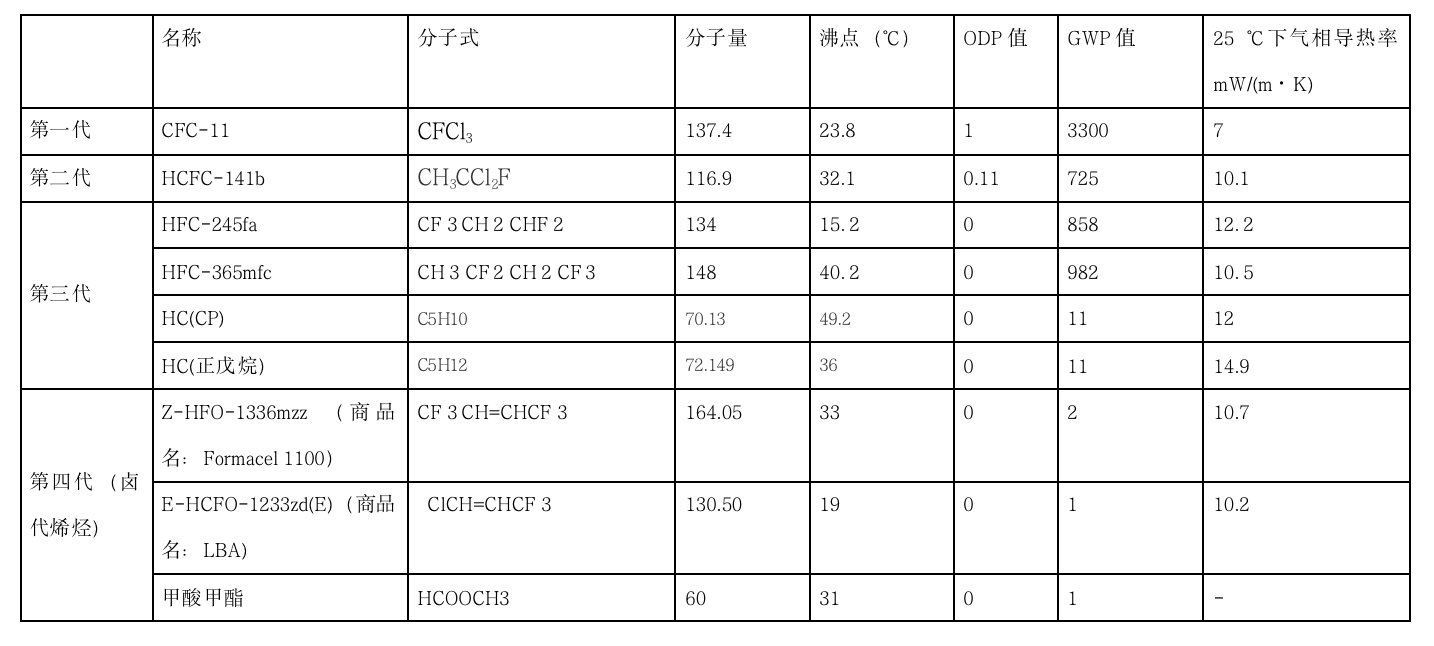

Table 2: Partial Physical Performance Indicators of First to Fourth Generation Blowing Agents

Current Development Status of Blowing Agents

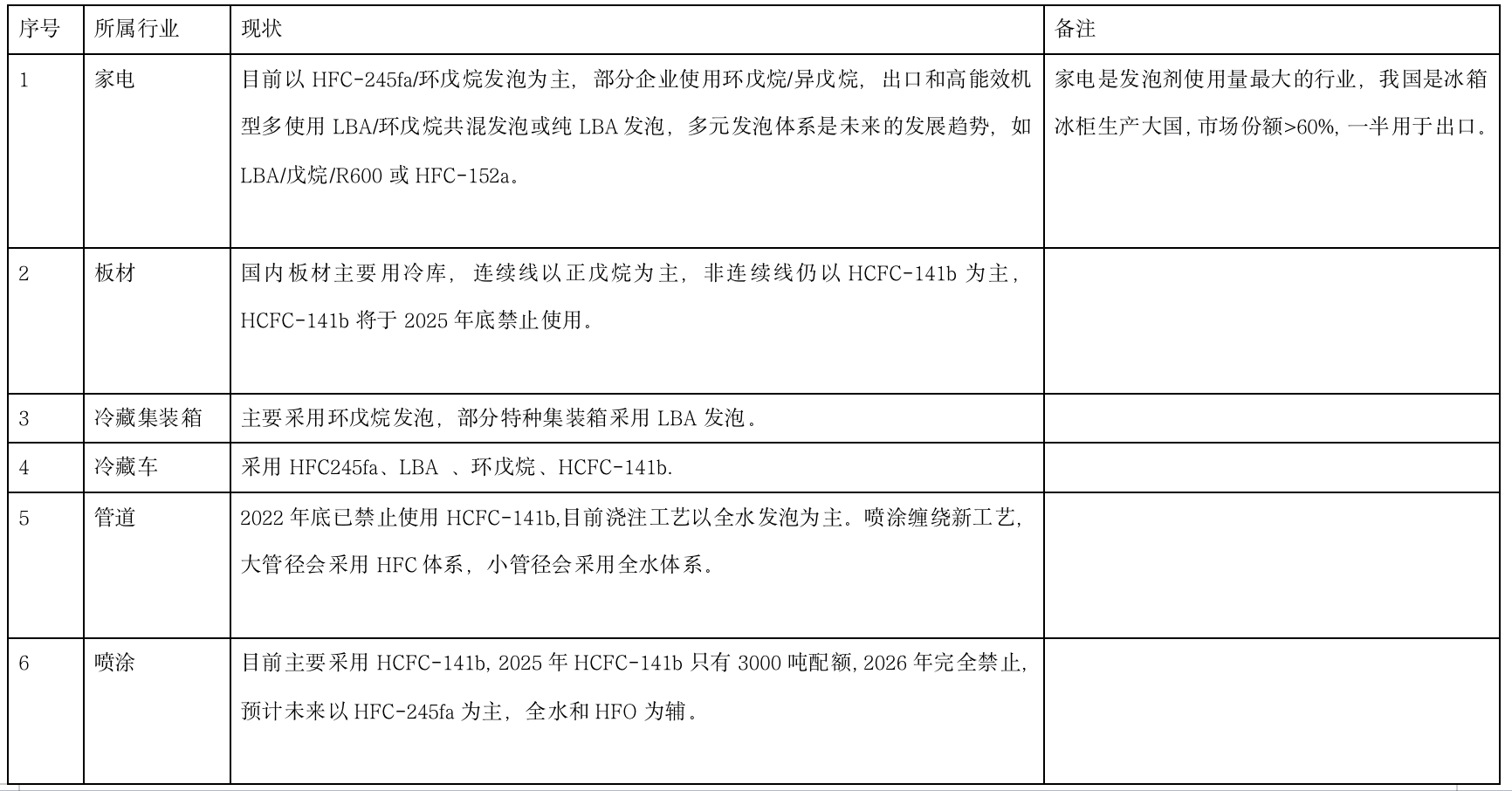

Polyurethane foam blowing agents are mostly used in the rigid foam industry, including household appliances, refrigerated containers, refrigerated trucks, sheet materials, pipes, and spray industries. Tables 3 and 4 provide detailed information on the current application status of blowing agents in China and abroad.

Table 3: Current Status of Polyurethane Rigid Foam Blowing Agents in China

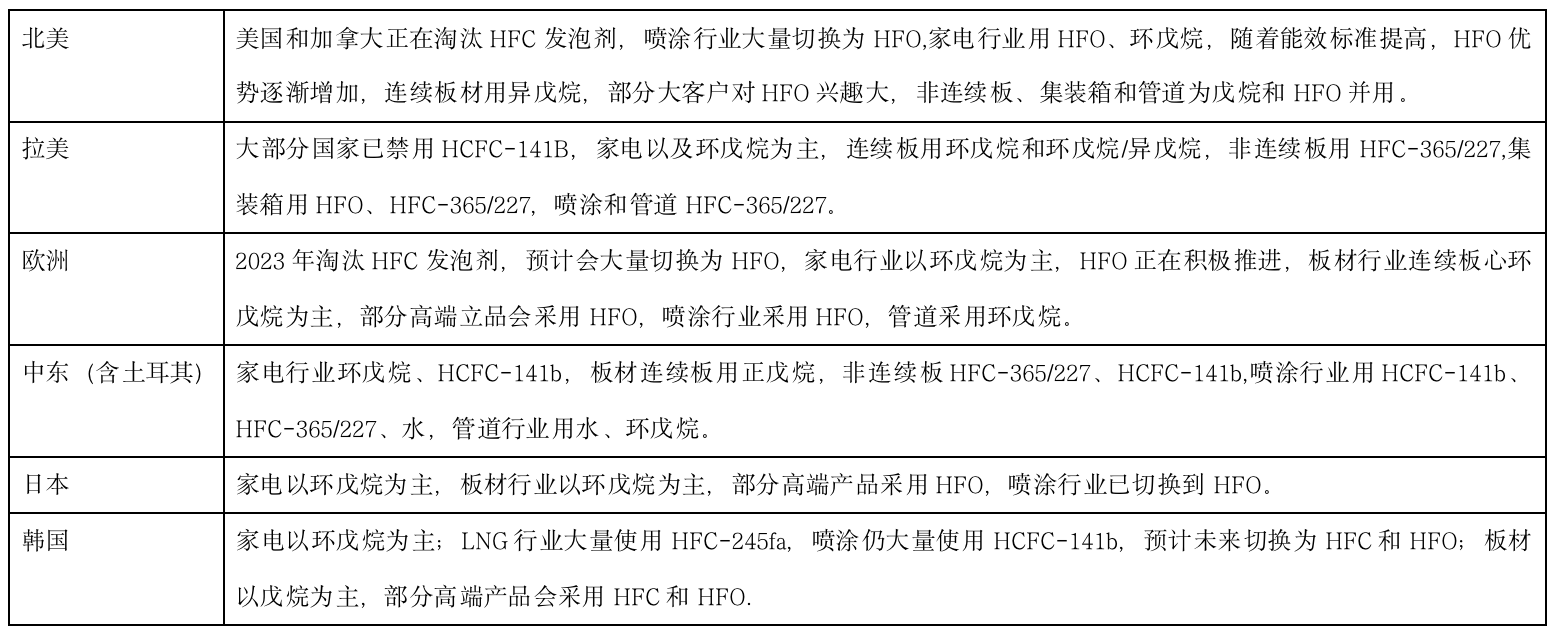

Table 4: Current Status of Blowing Agent Application Overseas

Future Development Trends of Blowing Agents

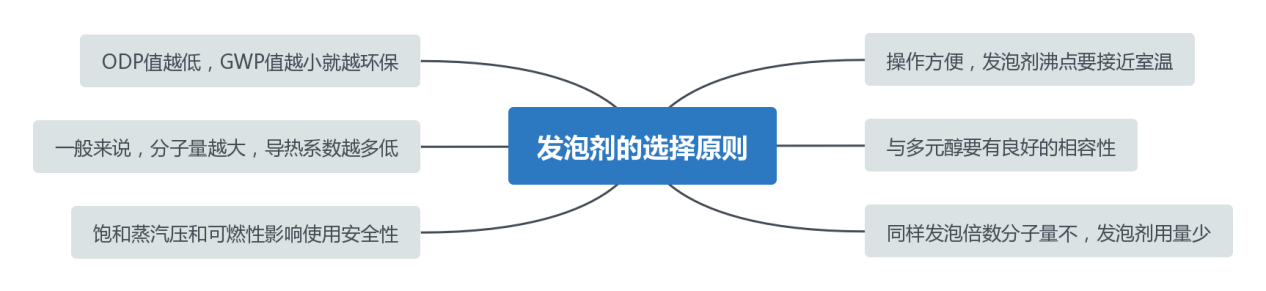

The future development trends of polyurethane foam machines are determined based on the principle of selecting blowing agents. The following diagram illustrates the factors to consider when selecting blowing agents:

With the accelerated process of phasing out HCFC-141b in China nearing completion, the polyurethane rigid foam industry is in urgent need of environmentally friendly next-generation blowing agents. Considering that the third generation fluorinated blowing agent HFC is not yet widely used in China and is restricted by the Kigali Amendment, the domestic polyurethane foam industry may directly transition to the fourth generation fluorinated blowing agents HFO-1336mzz(Z) and HCFO-1233zd(E), bypassing HFC blowing agents. Based on evaluation results, the fourth generation blowing agents are suitable for almost all applications in the polyurethane rigid foam industry, including household appliances, sheet materials, spray applications, and on-site casting. Although industrial-scale production has not yet been fully realized and the cost is high, with further reduction of HCFC-141b production capacity, environmental policy pressures, advancements in the production process of fourth generation fluorinated blowing agents, and cost reductions, the fourth generation blowing agents will find important applications in areas that require higher insulation performance and cannot be converted to pentane blowing agents. However, after the phase-out of HCFC-141b in China, refrigerators and freezers may continue to use cyclopentane and cyclo/isopentane systems in the long term due to their relatively low price, while products using HFO systems will primarily be exported to developed countries and regions. According to ChemNet's prediction, the sheet material sector will adopt cyclopentane and cyclo/isopentane systems, while the pipeline sector will mainly use water, with a small amount mixed with cyclopentane and cyclo/isopentane.

Contact Us

English

English  Español

Español  日本語

日本語  한국어

한국어  français

français  Deutsch

Deutsch  italiano

italiano  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt